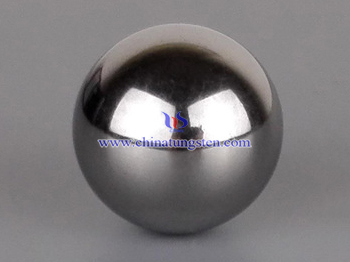

Tungsten Alloy Sphere for Weight

Tungsten Alloy Sphere

Our tungsten alloy Sphere are used to replace items which have previously been manufactured from Lead. By being able to supply lead-free replacement products, we hope to contribute to a safer and more environmentally-friendly world.

How and why tungsten alloy Sphere work in racing car

These small tungsten alloy Sphere can interact with engine lubricant and other matters. The tungsten component is chemically inert, stable and unaffected by temperatures encountered in application as a lubricant. Tungsten Alloy Sphere will not alter the carrier; exposure to them alters the way the metal of the friction surfaces interact with the lubricant.

Once the metals are exposed to the tungsten component in the carrier fluid, metal to metal friction is dramatically reduced, if not eliminated. This will increase engine efficiency and gas mileage. The end result is a dramatic reduction in wear, the friction that causes wear, heat, and power losses. This will also increase gas mileage.

Primitive man discovered that rubbing dead animal fat on things made them work better. Ever since, man has quested for better means of lubricating the things he (or she) has created.

Tungsten alloy Sphere as applied to automotive fuel systems

The lubricity of the tungsten alloy Sphere serves to lubricate fuel injectors, fuel pumps, valves and valve guides. Cylinder walls and piston rings benefit from contact with the tungsten Alloy Sphere. The .5 micron size of the Alloy Sphere easily passes through fuel injectors and filters. NOTE – Though the tungsten component is unaffected by temperatures of over 1200 degrees centigrade, tungsten Alloy Sphere have not been tested for use with catalytic converters. Not recommended for use with these systems.